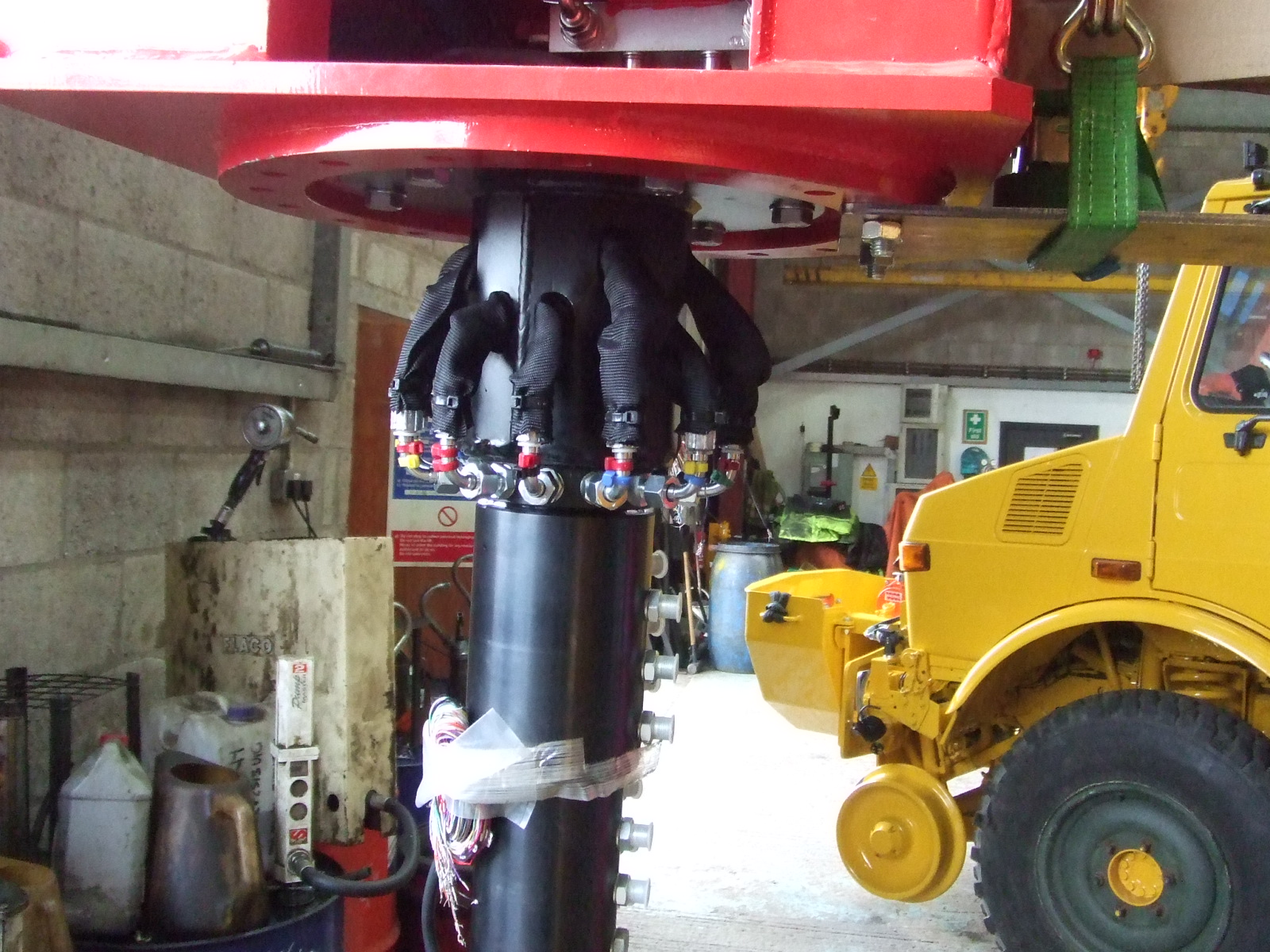

Here we have the U500 Arb unit that was demo’d on the APF show last year out in the field earning its crust! Starting with a bare Unimog we designed and fabricated the base, chip box and toolboxes all to the customers exacting specification. The challenge was full continuous slew on the platform, rising to the challenge this was achieved with a special combined hydraulic and electrical rotation unit. We designed and built a purpose built combined front DIN plate and additional front legs, this allows the vehicle to be levelled when sloping downhill and makes for an incredibly stable base. The platform has a 12m horizontal reach and can be used at full extent in all areas . The customer himself Peter Trayhorn (www.egdservicesltd.co.uk) researched and sourced the platform which is ideally suited to the type of line clearance and arb work that he gets involved with, the end boom being able to articulate either way is a particular useful. The Front chipper is a 10” Deucker with full remote control of chute lift, turn and connection to the rear chip box and all built and designed by ourselves. This was all the dream child of the owner Pete a longstanding customer of ours and it was certainly interesting work to achieve this!! Pete is over the moon with the finished product and has realised his lifetimes ambition to have a bespoke unit designed from the ground up to his remit! We must admit we are rather proud of what we have achieved ! Look out for further video clips of this unit, especially the remote chipper control and what we have dubbed the Supergun !!