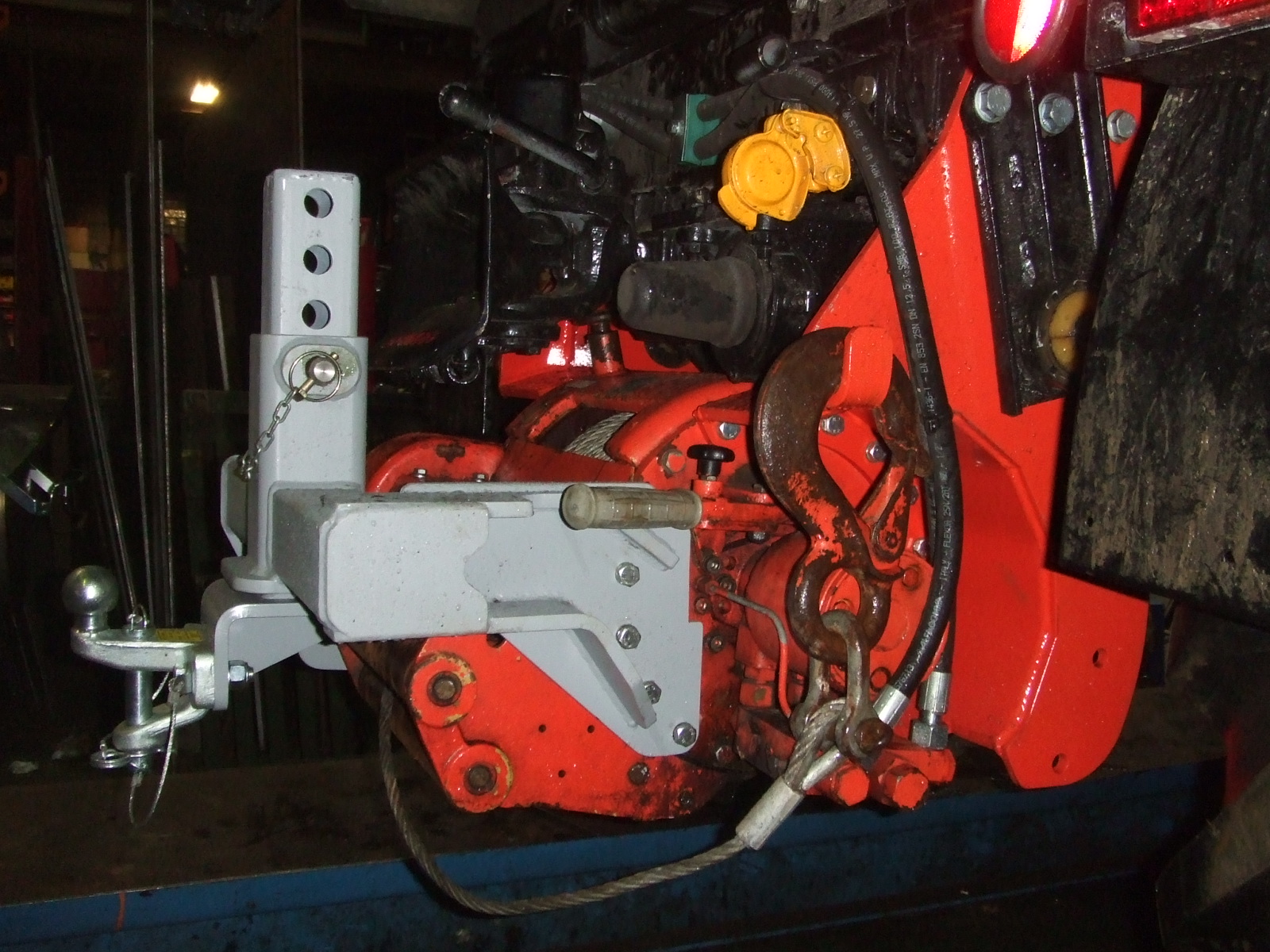

The winch acts as a natural counterbalance, the mounting was custom designed and fabricated by ourselves to fit around the existing PTO and equipment already at the rear. The customer also requested that he have a light duty drawbar integrated into the deisgn. This was in itself quite a challenge…the pictures show it still in primer as this was a last minute job with delivery to be before Xmas. Whilst the Unimog was here, we overhauled the gearbox as the splitter synchromesh was completely shot, brakes also required attention as the ALB was incorrectly set and the vehicle needed weighing on our weigh pads to arrive at the correct brake pressures with the front mounted chipper. Front spring spacers and shocker extension were also fitted to lift the front end with the chipper more or less permanently attached. We also fitted our external RPM engine control system, this then allows the operator to reduce engine rpm back to idle speed from either the front or back…using less fuel and also preventing from being used as the stress control is below speed.